CRA D-Plate Anchor for Facade Maintenance & Cal-OSHA Tie-Back

CRA D-Plate Anchor for Façade Maintenance & Cal-OSHA Tie-Back:

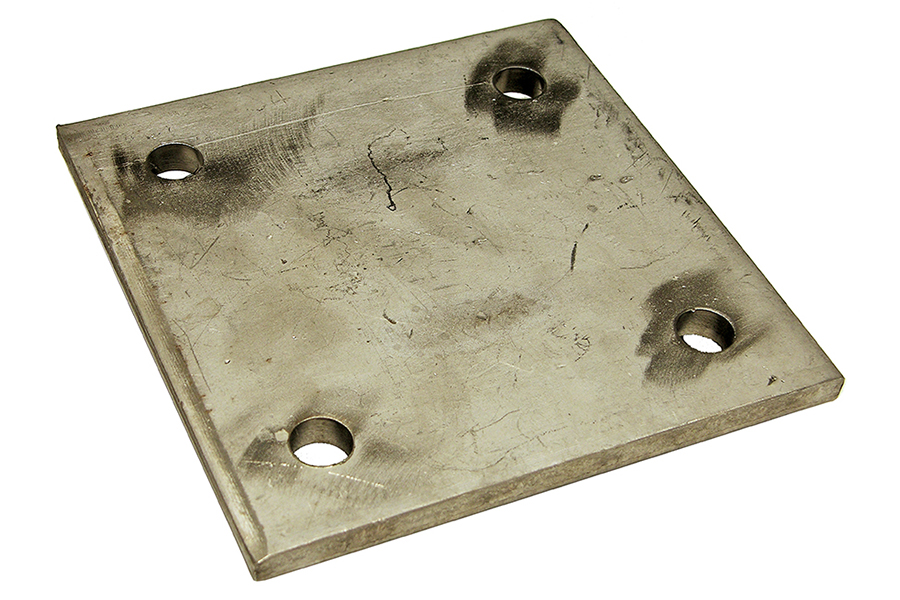

This version of our D-Plate anchor has the 2.0” ID cast loop top welded to it. This top is strong enough to meet the Cal-OSHA standard for window washing tie-back as well as our stringent requirement for façade access/maintenance equipment tie-back. The low-profile single user CRA D-Plate anchor is designed to be installed onto wood, steel, CMU walls, concrete embedded or concrete structure and can be utilized for fall protection, window washing suspension or as a horizontal lifeline intermediate anchor. This anchor comes pre-engineered to be installed with bolts, wedge anchors or field welds for installation on walls, floors, ceilings and other areas where applicable. It measures 6” x 6” and has our cast loop top welded to the plate.

The D-plate is not designed as a roof mounted anchor point as there is no way to waterproof it. Exterior wood framed walls can be flashed, and concrete/masonry walls require caulking on the edges. Fasteners are supplied by the customer. A variety of coatings/materials are available: galvanized, powder coated and stainless steel. Backer plates are also available.

- STRUCTURE ATTACHMENTS: Wood Beams, Wood Trusses, Steel Decking, Structural Steel, Masonry, CMU and Concrete

- ATTACHMENT HARDWARE: ½” Grade-8 Bolts, A-307 Threaded Rod, Concrete Wedge Anchors and Field Welds

- FALL PROTECTION CONFIGURATIONS:

- Stand Alone Anchor/Tie-Back Anchors for Fall Protection

- Cable Pass-Thru systems

- Window Washing Tie-Back Anchors

The State of California has special requirements for anchors on buildings over 36’ tall or 3 stories. As per Cal-OSHA Title 8, Article 5, Section 3291 titled: “Special Design Considerations – Permanent Rooftop Installations”. https://www.dir.ca.gov/title8/3291.html

(f) Roof Tie-Backs.

- Every building constructed 3 stories or 36 feet or more in height, shall have roof tie-backs or other permanent devices installed at the roof level for the purpose of securing or tying back suspended scaffold hooks or clamps and safety lines.

- Exceptions:

- Roof tie-backs are not required on buildings employing other acceptable means of permanently installed roof top maintenance systems specified in this Article or Article 6 (Powered Platforms and Equipment for Building Maintenance). Web link is here: https://www.dir.ca.gov/title8/3295.html.

- Roof tie-backs are not required on buildings constructed up to 4 stories or 48 feet in height when building maintenance can be accomplished using extension tools, ladders, approved ground equipment such as scaffolds, or aerial devices designed and used for positioning personnel.

- Exceptions:

- Such devices should be spaced at approximately 12-foot intervals; however, the spacing shall depend primarily on the availability of roof structural framing members of sufficient strength to safely carry applied loads. Tie-backs may be installed in structural parapets that are of adequate strength to sustain applied loads, but placement shall be as close to the roof level as practicable. Design criteria for tie-backs shall be as follows:

- Roof tie-backs shall have at least a 2-inch inside diameter closed “eye.”

- Tie-back assembly shall be hot-dip galvanized or afforded equivalent corrosion resistance.

- Assembly and anchorage provisions adequate to sustain a 5000 pound load applied in any direction without permanent deformation.

- Suspended scaffolds shall not be permitted unless roof tie-backs or equivalent anchorages are provided.

In review, here are the highlights to keep in mind when working in the Cal-OSHA anchor scenarios:

- Buildings 36’+ or 3+ stories tall: Required to have roof tie-backs unless you can achieve window washing and unscheduled maintenance from ground-based equipment.

- Buildings 48’+ or 4+ stories tall: Must provide anchors regardless of whether or not ground based equipment can be used. At a minimum they must be installed every 12’ on center around the entire building for unscheduled maintenance, and if utilized for window washing suspension, must be specifically designed to accommodate the particular window washing activities.

These standards are stricter than the standard window washing regulations set forth by OSHA, ANSI and IWCA in the 49 other states. Zero deformation at a 5,000-pound load requires special consideration in the engineering, design and manufacturing of the anchor. The supporting structure needs additional attention in order to sustain these loads as well. Super Anchor Safety has a full plethora of engineering documents that allows us to manufacture Cal-OSHA compliant CRA anchors in heights up to 36” tall. The extensive 3rd party, pre-engineered anchors follow very strict designs to make sure that you are provided finished products that comply with the strict Cal-OSHA standards. These anchors can be installed on wood decking, wood beams, metal decking, steel structure and concrete structures.

- Cal-OSHA Anchors are domestically made in USA

- Anchors are guaranteed for 5,000 pounds with zero deformation in any direction

- Extensive 3rd party Engineering, Calculations and Testing

- 2.0” Cast Loop Top rated for over 10,000 pounds

- 5,000 Pound zero deformation in any direction guaranteed

- Riser Heights from 8” up to 36”

- Attaches to Wood, Concrete, Steel and Metal Decking

- Made from A-36 Steel HDG, 304 SST or 316 SST

CRA Anchors are pre-engineered for your project eliminating the need for expensive, time consuming specialized effort by GC’s, architects or engineers to provide a fall protection plan. SAS has extensive 3rd party engineering documents, installation details, testing data and installation guidance ready at your disposal. The CRA’s can be used as end anchors, intermediate anchors as part of a horizontal lifeline system or as stand-alone 360-degree single user tie-off. The extensive testing, engineering and design criteria that we have done gives us the opportunity to offer you a fall protection anchor system that can be installed by your trade partners at a fraction of the cost of most commercial roof anchor systems on the market today.

With over 25 years’ experience, super Anchor Safety is the industry leader for commercial Roof anchors and horizontal lifeline systems. Used primarily on low slope applications, anchors can be custom fabricated for attachment to any type of structural support and to any architectural requirement. Our time-tested anchor designs are cost effective, easy to install, low maintenance and feature state of the art precast loop tops and pass through connector fixtures. We stock all the horizontal lifeline accessories needed for your project including IWCA window washing and Cal-OSHA compliant roof anchors. We can also supply 100% USA Manufactured/Certified anchors. Our simple design backed up with a full regimen of engineering documents is a cost effective, easy to install, low maintenance permanent fall protection fixture.

| Image | Part # | Connector Type | Plate Size | Material Finish | Weight | Use Rating |

|---|---|---|---|---|---|---|

| 1301-X | 2″ Loop Top | Custom Size | HDG Steel | 6.2 | 1 person PPE Anchor, Window Washing, HLL Systems, Façade Access & Cal-OSHA Window Washing | |

| 1301-G | 2″ Loop Top | 6″x6″x3/8″ | HDG Steel | 6.2 | 1 person PPE Anchor, Window Washing, HLL Systems, Façade Access & Cal-OSHA Window Washing | |

| 1301-S | 2″ Loop Top | 6″x6″x3/8″ | 304 SST | 6.2 | 1 person PPE Anchor, Window Washing, HLL Systems, Façade Access & Cal-OSHA Window Washing | |

| 1039-R | 6″x6″x3/8″ | Raw Steel | 2 | Backer Plate for all D-Plate Anchors | ||

| 1039-G | 6″x6″x3/8″ | HDG Steel | 2 | Backer Plate for all D-Plate Anchors | ||

| 1039-S | 6″x6″x3/8″ | 304 SST | 2 | Backer Plate for all D-Plate Anchors |

Part # – 1301-X

Connector Type: 2″ Loop Top

Plate Size: Custom Size

Material Finish: HDG Steel

Weight: 6.2

Use Rating/Compatibility: 1 person PPE Anchor, Window Washing, HLL Systems, Façade Access & Cal-OSHA Window Washing

Part # – 1301-G

Connector Type: 2″ Loop Top

Plate Size: 6″x6″x3/8″

Material Finish: HDG Steel

Weight: 6.2

Use Rating/Compatibility: 1 person PPE Anchor, Window Washing, HLL Systems, Façade Access & Cal-OSHA Window Washing

Part # – 1301-S

Connector Type: 2″ Loop Top

Plate Size: 6″x6″x3/8″

Material Finish: 304 SST

Weight: 6.2

Use Rating/Compatibility: 1 person PPE Anchor, Window Washing, HLL Systems, Façade Access & Cal-OSHA Window Washing